The Benefits of Prefabricated Cold Form Steel Modular Buildings: A Smarter Solution for Modern Construction

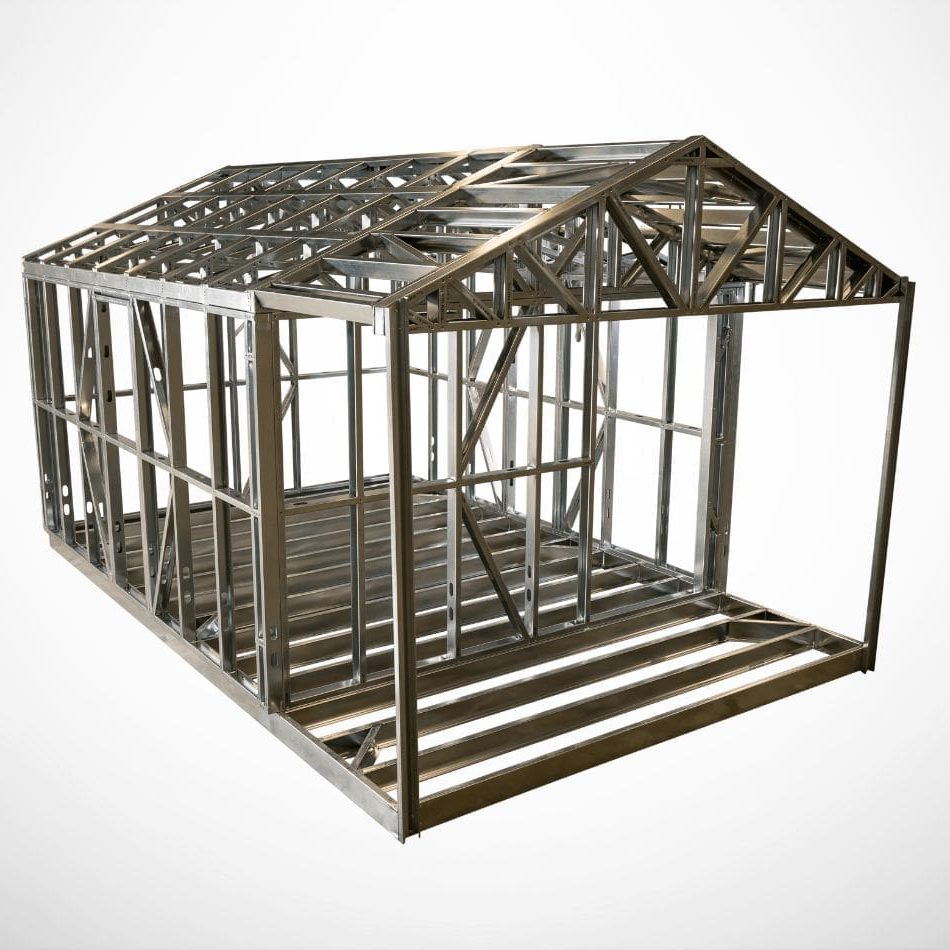

In today’s fast-paced construction world, developers and builders are constantly looking for smarter, faster, and more reliable building solutions. Prefabricated cold form steel modular building components have emerged as a leading choice, offering an innovative approach that addresses many of the challenges of traditional construction. From cost savings and durability to enhanced safety features like fire resistance, these structures provide long-term value while meeting the demands of modern projects. At B&T Manufacturing, “we’re proud to deliver prefabricated cold form steel modular building components that help our clients build better and smarter,” said Tim Torpey the General Manager.

Cost Savings Without Compromising Quality

One of the most significant advantages of prefabricated cold form steel modular building components is cost efficiency. Because components are manufactured offsite in a controlled environment, material waste is greatly reduced. Each piece is precision-cut, meaning fewer errors, minimal rework, and less need for costly onsite adjustments. The streamlined assembly process shortens construction timelines, which directly translates into labor cost savings. Faster build times also mean earlier occupancy, allowing owners to generate revenue or operational benefits sooner.

Prefabricated cold form steel building components also offer predictable pricing. With much of the work done in a factory setting, builders avoid many of the common variables that drive up costs in traditional construction, such as weather delays, material shortages, or onsite damage. This predictability makes budgeting and project management easier and more reliable.

Durability That Stands the Test of Time

Steel is one of the most durable building materials available, and prefabricated cold form steel modules are engineered for strength and longevity. These structures can withstand harsh weather conditions, including high winds, heavy snow loads, and seismic activity, far better than many traditional building methods. Their inherent strength means they require less maintenance over time, resulting in lower long-term upkeep costs.

Additionally, steel is resistant to pests like termites that can compromise the integrity of wood structures. This durability provides peace of mind for owners and developers looking for structures that will retain their value and performance for decades.

Fire Resistance and Safety Advantages

Safety is a top priority on any construction project, and prefabricated cold form steel modular building components offer superior fire resistance compared to traditional materials such as wood. Steel is non-combustible, meaning it will not contribute fuel to a fire, and it maintains its structural integrity longer under extreme heat. This quality can provide valuable time for occupants to evacuate safely and for emergency responders to act in the event of a fire.

In addition to fire resistance, prefabricated cold form steel modules are built to meet or exceed stringent building codes and safety standards. Because they are manufactured in a controlled setting, quality control measures are strictly enforced, ensuring every module is built to the highest specifications before it even reaches the job site.

Sustainability and Environmental Benefits

Prefabricated cold form steel modular building components also contribute to more sustainable construction practices. Steel is highly recyclable, and most prefabricated steel modules are made from recycled materials. At the end of a building’s life cycle, its components can often be repurposed or recycled, reducing environmental impact.

The efficient manufacturing process also generates less waste and requires less energy compared to traditional building methods. With growing demand for environmentally responsible solutions, prefabricated steel buildings align well with green building initiatives and certifications.

Conclusion

Prefabricated steel modular buildings are reshaping how we think about construction. Combining cost savings, durability, safety, and sustainability, they provide a smart solution for a wide range of applications, from commercial and industrial projects to educational facilities and beyond. At B&T Manufacturing, we are committed to delivering steel modular buildings that help our clients achieve their goals with confidence and efficiency.

Key Takeaways:

- Prefabricated cold form steel modular building components offer significant cost savings through reduced material waste, faster build times, and predictable pricing.

- Steel structures provide exceptional durability, low maintenance requirements, and superior resistance to pests and extreme weather.

- These buildings offer enhanced fire resistance and safety, along with environmental benefits through the use of recycled materials and sustainable manufacturing practices.